CASE STUDIES

Case studies

AMC Consultants has performed more than 10,000 projects for our clients around the world. The below is just a small sample of our successes. Click here to find out who our clients are, and click here to find out what they have to say about working with AMC.

By Camila Rivera

•

25 Apr, 2023

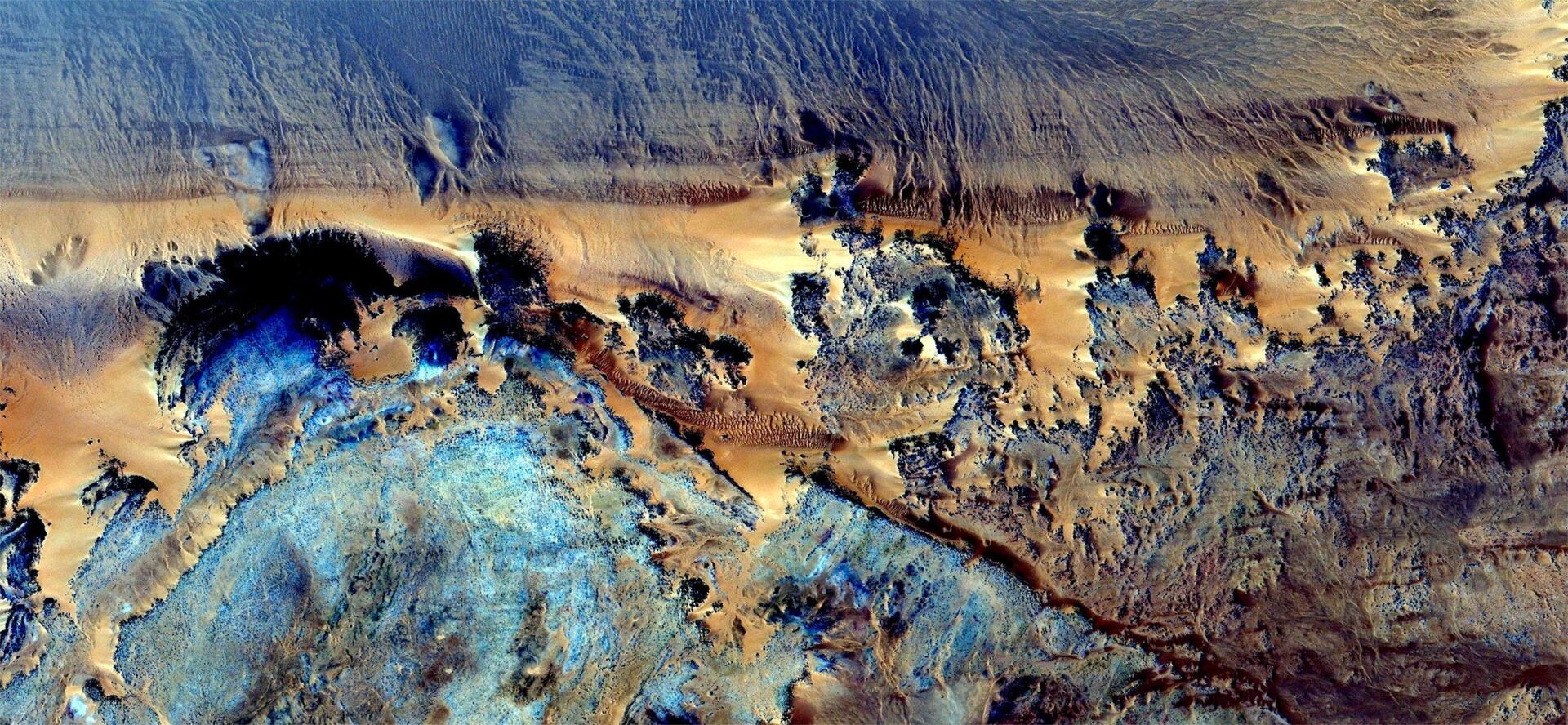

Project achievements: Undertaking the mining component of the DFS, LG pit optimization, Strategic mine plans, Pit designs, Identified the wet overburden surface to improve cashflow and NPV by selectively mining overburden with dredges above the ore, Tactical mine plan with material balance, destination and haulage.

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights