Geological audit as part of CRIRSCO public reporting vs. Russian GKZ expertise

The difference in approaches to data validation.

Remember the drudgingly balancing geologist, from the AusIMM 2014 Guide to Good Practice, illustrating the risky approach to resource estimates? He is still here and still trying to stabilize that overturned pyramid of sophisticated modeling that is based on unverified data.

Is the geologist’s data, in fact, precise and accurate? Does the data contain only random errors, so the balancing geologist would keep his legs and steady the pyramid, having done several outstanding somersaults (the consequences of which would inevitably emerge at some point)? Is there bias concealed in the sound-looking data? So says the geologist’s hat… And the rumble from the fall of the pyramid will excite the surroundings despite all the geologist’s acrobatic efforts.

We would not know the future of our fellow geologist and his pyramid unless we assess the quality of his data. Data validation is a critical step to ensure it is clean, correct and thus useful for any resource estimates and general project assessment. The importance of data validation is an axiom that is independent of the industry, project or country. Having stated this, it is interesting to note that the approaches to data validation during geological audit for the purposes of CRIRSCO-type reporting is different from the approaches taking place during technical expertise carried out by the State Committee for Reserves (the GKZ) in Russia.

Disregarding the differences in resource/reserve classification between the two systems and the differences between the public vs. the highly confidential reporting in the Russian system, both the CRIRSCO reporting and the GKZ expertise deliver the same desired result – the approved numbers for mineral resources and ore reserves. However, the scope of geological audit required to achieve the approved tonnage and grade numbers is very different.

International codes from the CRIRSCO family provide general guidance for public reporting, leaving the assessment of the procedures, the data validation and the details of reporting for the professional judgment of a Qualified/Competent Person – QP/CP. The Russian system for reporting on mineral resources and ore reserves is strictly regulated. The “Classification of reserves and prognostic mineral resources” (2006), the “Guidelines for the application of the Classification of reserves” (2007) and “Requirements for the scope and submission guidelines for materials presented for state examination for estimating the reserves of solid minerals” (2011) clearly establish the rules, procedures, and scope of work for the preparation of materials for estimating reserves and submitting them to the state expertise.

Following the official definition, the state expertise is carried out in order to create conditions for a rational integrated use of the subsoil, state record-keeping of mineral reserves and license areas provided for mining and for purposes not related to the extraction of mineral resources, determination of payment for the use of subsoil, boundaries of subsoil license areas provided for use, assessing the reliability of information on the quantity and quality of explored mineral reserves, other properties of the subsoil, determining their value or hazard (Clause 2 of the Regulation on State Expertise, 2005). The data reliability is therefore put to the end of the list. It is still very important, but it is even more important to follow the prescribed procedures and regulations in order to pass the GKZ expertise. Now, why do I see the phantom of that balancing geologist from Figure 1 again?

During their audit, the GKZ experts work with a finalized version of a technical report that has been written by either the Company itself or a subcontractor consulting company that specializes in technical reports for GKZ. The expert reviews the report based on his/her experience and knowledge of the project and the review itself is (surprisingly) not limited by any regulatory documents. The expert can request any primary data if he/she identifies deviations from methodological documents or doubtful conclusions. But digging deep into primary data, as required by the CRIRSCO reporting codes, and beyond the scope of the report is not part of a regular GKZ expertise. Consequently, the Company may at the end of the day be surprised to have different results of what seemed to be the same process of geological audit but carried out according to different standards and for different purposes.

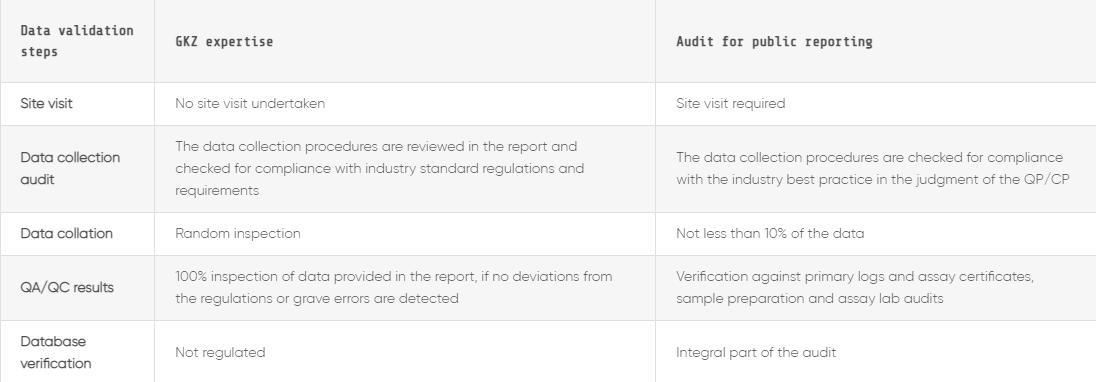

The main differences in approaches to data validation between the two systems are provided in Table 1 and explained below in broad brushstrokes.

Table 1 Differences in approaches to data validation during geological audit as part of GKZ expertise vs. CRIRSCO public reporting.

Site visit

Figure 2 Happy principal AMC geologist, Olga Almendinger carrying out a site visit.

The requirement for a site visit is a crucial difference between an audit carried out by a consulting company as part of a CRIRSCO-style reporting, and a GKZ expert review. The GKZ expert would not go on a site visit, while it is mandatory for public reporting on mineral resources.

The field audit comprises a review of the whole chain of exploration activities and their results, starting from the topographic base through sample collection to preparation, and finishing with the methods of packing samples on-site before shipping them to the assay laboratory.

Data collection audit

Data collection review in the field involves:

- Methods of georeferencing trenches, underground workings, and collars.

- Checking coordinates on-site with GPS.

- Drill hole survey methods, their accuracy and equipment used.

- Techniques of trenching, opening underground workings and drilling, including technical details like core diameters, the drill solutions, etc.

- Logging procedures for trench surface outcrops and underground walls.

- Practices for determining core recovery.

- Geological control during drilling and marking core at the drill site.

- Laying out of the core, methods of core transportation and measures taken to ensure core integrity.

- Core logging, including the inspection of the logging facility, reviewing the experience of the geologists doing the logging, the skills to visually assess the grades of the commodity, the use of XRF express analysis, the presence of logging procedures and codes for all categories, photo logging.

- Geotechnical logging procedures.

- Methods for measuring specific gravity.

- Sampling techniques in the field and their correspondence to the company standard operational procedures.

- Measures taken to ensure sample representativeness.

- Core splitting techniques, the presence of a marking line for core cutting and who is responsible for marking the core, the position of the cutting line.

- Sample preparation facility and flowsheet audit.

- Analytical laboratory audit.

- Analytical protocols and their detailed documentation.

- Sample storage and security.

Depending on the reliance on historical or even recent sampling, the auditor may take verification samples during the site visit.

Data collation

Within the framework of the GKZ expertise, the need for the collation of data with primary materials is decided by the expert.

During the audit underlying the public reporting, the correspondence of the database to the primary drill hole logs and, more importantly, to the actual in situ geology is verified in the field based on the core reject samples.

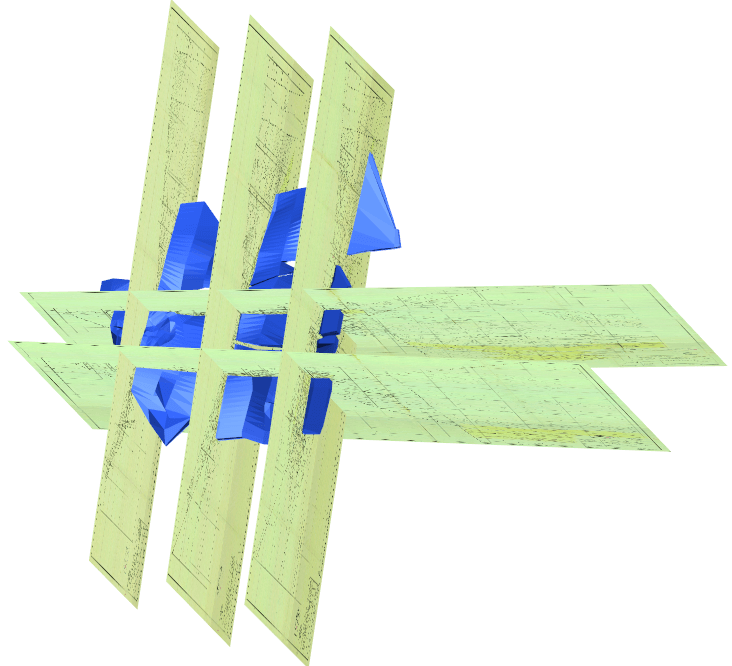

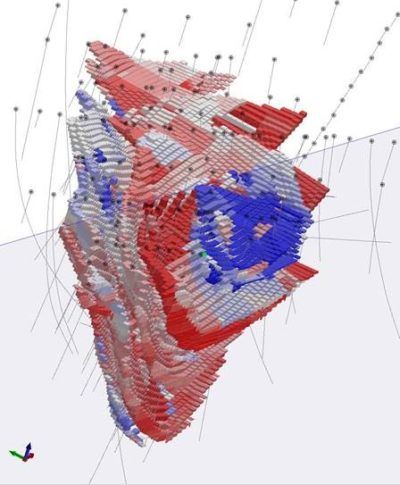

Figure 3 An example of a 3D geological model of the deposit constructed based on digitized cross-sections.

3D Models for projects with historical exploration are often built based on digitized sections and plans that have been initially manually drawn and represent someone’s geological and structural interpretation and generalization of the primary logs. As a consequence, the geological model and interpretations should also be checked against the database.

QA/QC results

GKZ expertise is focused on reviewing if the QA/QC results comply to industry standard regulations and guidelines, which include several documents.

- Industry-standard OST 41-08-249-85 “Sample preparation and organization of quantitative analysis in the laboratories of the Mingeo of the USSR. General requirements” dated 1985.

- “Requirements for provision of the reliability of sampling ore deposits” dated 1992.

- Industry-standard OST 41-08-272-04 “Methods of geological quality control of analytical work” dated 2004, which is the main document used as a guideline for QC during GKZ review.

OST 41-08-272-04 requires that not less than 5% of the pulp duplicates are re-analyzed at the primary laboratory (internal QC), aimed at checking the reproducibility of assay results. The samples that pass the quality criteria for the internal QC are then sent to a reputable umpire laboratory for additional check analysis (external QC), aimed at checking for bias that the primary laboratory may introduce into routine assay results.

The batches for internal and external quality control are formed by dividing the assay population into grade classes, which are also prescribed by OST for each commodity. Each grade class should be represented by not less than 30 samples. The internal and external quality control should be carried out periodically – every quarter, every half-year, or every year, depending on the number of routine samples assayed during the period under control.

OST 41-08-272-04 does not postulate the use of certified reference materials (CRM) or blanks, however, it provides methods for analyzing CRM data. The data is to be accumulated and reviewed in the same manner as the internal and external duplicate results – at the end of a certain period. This allows estimating the general levels of accuracy and precision within the control period, however, makes it hard to trace the problems to certain sample batches, or solve the problems promptly.

The voluminous tables of internal and external quality control results are provided as Appendices to the GKZ reports on reserves. They are rarely checked against the primary laboratory certificates by GKZ experts. Moreover, according to the OST the duplicate data should be cleaned of outliers before it is analyzed. The OST does not require the report to include a list of outliers excluded from the quality control check, thus the actual number of samples that went through the quality control checks is not reported.

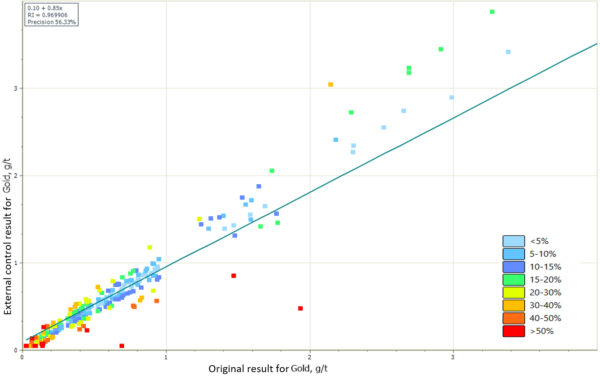

QC data accumulation and analysis at the reporting stage contradicts the proactive purpose of QA/QC procedures. The idea behind the use of QC samples is to provide the ability to instantly identify and address any problems associated with individual batches of samples, taking into account that problems may have originated anywhere from the original sample collection to the final assay.

An industry best practice for CRIRSCO public reporting is to provide the auditors with results of routinely and blindly inserted control samples, such as certified reference materials, blanks (course/pulp) and duplicates (field/course/pulp) into sample batches, so that the quality of any stage of sampling, sample preparation or assaying processes can be evaluated. AMC strongly advises company geologists to carry out immediate analytical processing of QC samples results as they are delivered from the laboratory, as it facilitates decision making in accepting or rejecting assays from certain batches or promptly addressing problems at all stages of working with samples.

An independent QA/QC audit for resource evaluation under the CRIRSCO codes is not limited to sampling and geochemical analyses. The audit includes a review of QA/QC principles applied to the collection of density data. AMC strongly advises to set up a QA/QC system for each step of the density measurement process, which should be documented and tested prior to implementation. Besides checks on instrument calibration, the quality control measures should include duplicate measurements.

Database verification

While database verification is not regulated in the GKZ expertise, the international audit usually involves comparing approximately 5-10% of records in the database with their original values in the analytical certificates, as well as collating all the outlier grade results with original certificates. In addition, the database is checked for non-numeric values in the assay data used for resource modelling and the geological and mining software allows to check for errors in hole orientation surveys.

The voluminous tables of internal and external quality control results are provided as Appendices to the GKZ reports on reserves. They are rarely checked against the primary laboratory certificates by GKZ experts. Moreover, according to the OST the duplicate data should be cleaned of outliers before it is analyzed. The OST does not require the report to include a list of outliers excluded from the quality control check, thus the actual number of samples that went through the quality control checks is not reported.

QC data accumulation and analysis at the reporting stage contradicts the proactive purpose of QA/QC procedures. The idea behind the use of QC samples is to provide the ability to instantly identify and address any problems associated with individual batches of samples, taking into account that problems may have originated anywhere from the original sample collection to the final assay.

An industry best practice for CRIRSCO public reporting is to provide the auditors with results of routinely and blindly inserted control samples, such as certified reference materials, blanks (course/pulp) and duplicates (field/course/pulp) into sample batches, so that the quality of any stage of sampling, sample preparation or assaying processes can be evaluated. AMC strongly advises company geologists to carry out immediate analytical processing of QC samples results as they are delivered from the laboratory, as it facilitates decision making in accepting or rejecting assays from certain batches or promptly addressing problems at all stages of working with samples.

An independent QA/QC audit for resource evaluation under the CRIRSCO codes is not limited to sampling and geochemical analyses. The audit includes a review of QA/QC principles applied to the collection of density data. AMC strongly advises to set up a QA/QC system for each step of the density measurement process, which should be documented and tested prior to implementation. Besides checks on instrument calibration, the quality control measures should include duplicate measurements.

Database verification

While database verification is not regulated in the GKZ expertise, the international audit usually involves comparing approximately 5-10% of records in the database with their original values in the analytical certificates, as well as collating all the outlier grade results with original certificates. In addition, the database is checked for non-numeric values in the assay data used for resource modelling and the geological and mining software allows to check for errors in hole orientation surveys.

Екатерина Пеленкова

Анализ данных и QA/QC

Ekaterina is a geologist with more than 15 years of industry experience. She has focused on data management and QAQC systems for most of her career to date. Ekaterina combines skills in geostatistics, modelling, QAQC, and sampling, with software skills in a variety of mining, database, geostatistical and GIS packages. This provides her with a strong background for reviewing and advising on using data as a basis for both geological modelling and resource estimation for a variety of commodities and deposit types.

In addition to both consulting and company roles, Ekaterina has experience as a presenter and teacher of courses in data management and QAQC.

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights