Why characterization of mineralization affects profits: Gold in West Africa

Gold projects are well recognized for their variety in mineralization style between deposits, and variability within deposits. At times both variety in mineralization style and internal variability can be present in very close spatial association, such as within a single open pit. Gold deposits in West Africa commonly display considerable variation across a single project area, but geological evaluation, mine planning, production and mineral processing streams often fail to fully account for the range of characteristics. The consequences can, at minimum, be an unrecognized shortfall in optimizing mineral exploitation and financial return, but can also threaten the viability of the operation.

This article focuses on the need for all technical disciplines and management levels within the mining stream to be well versed in the characteristics of an operation’s mineralization, in order to both maximize the value generated and to minimize the economic risks, by incorporating this knowledge into each relevant process.

There are many elements that collectively define what is referred to here as mineralization character. Some of these are:

- The geometry of the mineralization, such as shape and lateral continuity.

- How a boundary is defined, for example by structure, lithology, alteration, or grade.

- Grade characteristics at the boundaries, which may be sharp, gradational, or very irregular.

- Internal grades variability both within and between drilling/sampling intersections.

- The degree to which a zone has been disrupted by folding and faulting.

- Geometallurgical parameters, such mineralogy and hardness.

While these largely appear to be of interest only for geological activities, most technical and production personnel will have some appreciation of how these characteristics are expressed and distributed in the orebodies that they deal with. However, proper accounting for the ways in which these characteristics can affect metal produced is often lost in the daily production processes. Poor operational performances arise through persistent use of entrenched procedures, particularly where the ore characteristics have changed from those recognized at the time when procedures were first established. This effect can be exacerbated where significant levels of automation have been introduced, and the systems fail to adequately account for variability or to respond to change.

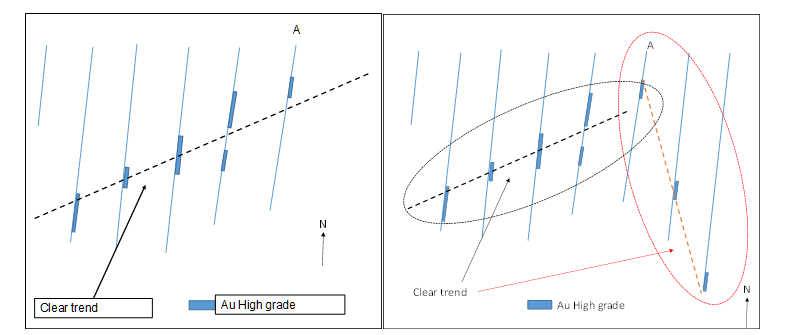

The following example of ore distribution is based on observations at a West African deposit, but has been simplified and exaggerated for illustration. The main observable (dominant) feature is a broad trend inclined gently to the left, as shown in Figure 1 (left hand box). In the right hand box, a local subordinate trend has been added.

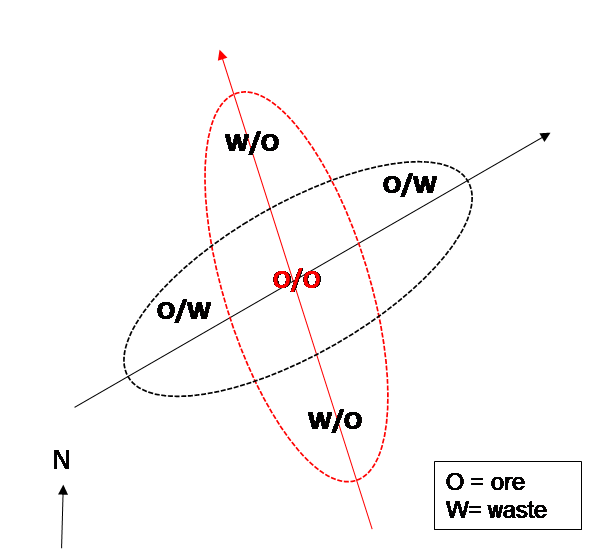

Semi-automated interpretation and estimation for grade control is undertaken into a block model, using controls that honour the dominant left-inclined trend, but ignore the subordinate cross-trend. A scenario of potential misclassification through poor ore characterization during grade control is schematically illustrated in Figure 2.

Misclassification occurs as both dilution, where predicted ore is actually waste (O/W), and ore loss, where predicted waste is actually ore (W/O). The win-win area is in the centre (O/O), where ore is both predicted and realized. In an operational situation, it is easy to envisage significant concurrent unplanned dilution and ore loss, even before mining dilution has been incurred.

AMC selected a small part of the deposit, and considered a simple set of scenarios to quantify the profit implications that might be achieved from improved classification of ore due to better characterization. The scenarios envisaged a 3% reduction in tonnage and a 3% increase in mined grade (Table 1). While the net effect is a negligible improvement in metal revenue, the mining of 25 kt less material for a higher grade (revised case) should lead to a chain of benefits, ranging from mining and material movement, through to plant throughput and processing reagent use. Under the revised case, comparable ounces to the base case will be mined, but with an expected increase in profitability

Table 1 – Ore classification scenarios

| Description | Units | Scenario 1 | Scenario 2 |

|---|---|---|---|

| Tonnes | t | 800,000 | 775,000 |

| Grade | g/t | 1.5 | 1.55 |

| Ounces | oz | 38,581 | 38,621 |

| Price | USD | 1200 | 1200 |

| Revenue | USD | 46,297,000 | 46,345,000 |

Ore misclassification during grade control is just one of the implications of a failure to fully account for variable mineralization character. The following are examples of other potential opportunities for improvement, based on an expectation that all technical and management personnel have an appropriate understanding of the diversities in mineralization character across a project. These examples are particularly relevant to a scenario, common in West Africa, where ore is drawn from multiple, spatially-distributed deposits, none of which is sufficient to individually sustain the project:

- Strategic: Optimal location of processing plant, selection of cut-off grade, and prioritizing of areas for further evaluation and investment.

- Mine planning: Multiple ore source pit optimization, variable scheduling of production rates, taking account of different mineralization styles.

- Mining production: Flexibility in grade control, blasting, available mining equipment, and stockpile management.

- Reconciliation: Rigorous procedures that track variability both project-wide and at a local deposit level.

- Metallurgical: Optimization of crushing, milling, and recoveries from the range of ore sources, through geometallurgical modelling and tracking of characterized material.

Text by Chris Arnold.

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights