The unseen value of preserving and careful handling of borehole core: a geotechnical engineering perspective

Introduction

The value stream of borehole core commences as soon as planning begins for the exploration drilling programme. The location, diameter, depth, and type of drilling are determined during this stage. This planning phase is usually conducted solely by the exploration geology team, with the primary focus on identifying a resource. Very little attention appears to be given to ensuring the full value of the core is realized, particularly pertaining to geotechnical requirements. The matters concerning the collection of geotechnical data have been previously highlighted in earlier AMC Digging Deeper editions (May and November 2016), and are repeated in this publication (Metcalfe, J).

Unfortunately, even if the exploration programme incorporates geotechnical requirements as part of the planning process, the value of ensuring good quality drilling, core recovery, handling, and storage does not appear to receive high priority in the execution of the programme. In many cases the sole purpose is to recover as much of the core as possible, and eventually photographing it sometime after it has been boxed and transported to the core shack for geological logging and sample selection (for assay purposes). Generally, the mineralized portion of the core is given more attention than the barren core. By the time it is realized / highlighted that appropriate geotechnical core logging is required, the core is likely in a state that is no longer representative of the in situ condition of the lithological sequence through which the borehole was drilled.

This article highlights the importance of preserving the integrity of the core, from the time it is extracted until such time that the geotechnical core logging is conducted. This is particularly important given that one of the critical parameters for mine design pertains to the quality of the core; i.e. the Rock Quality Designation (RQD).

Maintaining the integrity of the core

Preserving the integrity of the core commences during drilling. Often the focus of exploration drilling is on the quantity of metres drilled per shift, instead of on the quality of the core recovered. A consequence of this approach is that the core may be broken or crushed, implying that the intersected ground conditions were blocky (Figure 1).

The process of handling the core boxes between the drill rig and the core shed is equally important to maintain the integrity of the recovered core. Poorly handled core may result in either core loss (falling out of the box) or introduce additional mechanical breaks (Figure 2), which may be mistaken for natural fractures (particularly in a strongly foliated rock mass). The person conducting the geological core logging programme should be suitably trained to differentiate mechanical breaks from naturally occurring fractures, as these have a profound effect on determining the RQD.

Storage of the core following geological (and hopefully geotechnical) logging is just as critical as drilling and core handling. Core recovered during exploration forms part of the mining asset, and should the mine be transferred to another mine owner, the core remains part of the asset. Incorrectly stored core may deteriorate due to exposure to natural elements (e.g. freeze-thaw cycles or exposure to heat or moisture). Examples of deterioration include degradation of, or missing core falsely representing the in situ rock mass geomechanical conditions. For example, Figure 3 shows the deterioration of clay intersections in a schist-hosted orebody and carbonaceous mudstone intersections,

One of the key rock mass parameters that requires correct and valid determination is the RQD, which is a measure of how ‘good’ the in situ rock mass may be. Deere and Deere, 1989 defined the RQD as an “index of rock quality in which a modified core recovery percentage is obtained by counting only pieces of sound core 100 mm or greater…”. Measurement of the RQD should only be undertaken on rock-like material, and not on soils or highly weathered or sheared material.

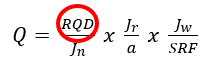

The RQD value is used in rock mass classification systems as part of quantifying the quality of the rock mass. The results of the rock mass classification systems (in particular Barton’s NGI Q-system and Bieniawski’s Rock Mass Rating) are used as inputs for geotechnical designs pertaining to pit slope design, open stope dimensions, tunnel designs, stope support designs, pillar designs, crown pillar stability analysis, dilution control, etc.

Barton’s NGI Q-system relationship:

Bieniawski’s (1989) Rock Mass Rating system applies a value to the following six parameters: Uniaxial Compressive Strength, RQD, spacing of discontinuities, conditions of discontinuities, groundwater conditions and orientation of discontinuities. The sum of the values assigned to the parameters is used to classify the rock mass quality (Table 1).

Table 1 Bieniawski’s rock mass quality determination

Rock Mass Rating value interval

0 – 20

21 – 40

41 – 60

61 – 80

81 – 100

Rock mass quality

Very poor

Poor

Fair

Good

Very good

This illustrates that incorrect recording of the RQD may have a material impact on the results of geotechnical designs.

Conclusion

Preserving the quality of drill core is critical to geotechnical design for both green- and brownfield projects. The determination of the RQD from borehole core is a key input into determining the quality of the rock mass. Experience shows that the RQD is usually measured during the geological core logging process (and usually includes RQD determination on ‘non-rock-like material’), however by the time the core is photographed or geotechnically logged, mineralized zones are split, samples are missing or weak material in the core has degraded to the extent that appropriate determination of the RQD cannot be undertaken.

References

Bieniawski, Z. T. (1989). Engineering rock mass classifications: a complete manual for engineers and geologists in mining, civil, and petroleum engineering. Wiley-Interscience. pp. 40–47.

Deere, D.U and Deere, D.W., February 1989, Rock Quality Designation (RQD) after 20 years, Department of the Army, US Army Corps of Engineers, Washington, DC, Contract No. DACW39-86-M-4273

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights