Narrow vein minimum dilution case study

AMC has conducted numerous studies to reduce dilution for mechanized narrow vein (NV) mining methods in operating mines. Methods have included longhole open stoping (LHOS) and mechanized cut and fill (CAF). Dilution can be classed as planned or unplanned. Planned dilution accounts for waste material incorporated into the stope when designing practical mining shapes. Planned dilution will depend on the vein geometry, thickness, orebody dip, and local ground conditions. Unplanned dilution consists of waste which is mined due to overbreak, which may result from poor drilling or blasting or as any waste incorporated during mucking. This article presents a high-level discussion of a study conducted by AMC to determine the optimum (minimum) dilution that could be reasonably applied to a NV orebody.

Vein characterization

The dilution study began with vein characterization. The broad aim was to identify the general variability in vein width, geometry, and lateral extent (strike and dip) and, as far as practicable, to identify geotechnical conditions that may determine the applicability of various mining methods. The findings included:

- Consistent vein strike 1,500 m.

- Vein width ranging from 0.5 m to more than 5 m.

- Ground condition ranging from poor to good, across strike and depth extents.

- Cemented rockfill and waste rock considered to aid ground support.

- LHOS and CAF used at the mine, with potential to optimize sublevel spacing and mining sequence.

Optimized dilution scenarios

Using the results of the vein characterization study, it was concluded that the minimization of dilution for LHOS and CAF would be based on:

- Vein widths of 1.5 m, 2.25 m, 3.5 m and 5 m.

- Varied ore drive dimensions, and rectangular and shanty-back profiles.

- Orebody dips of 61°, 66°, 68° and 72°.

Formulae

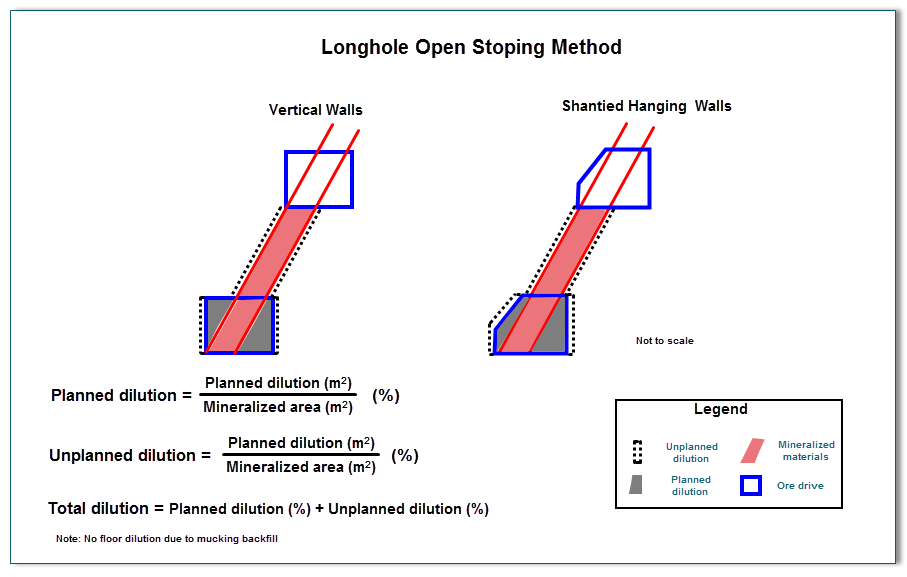

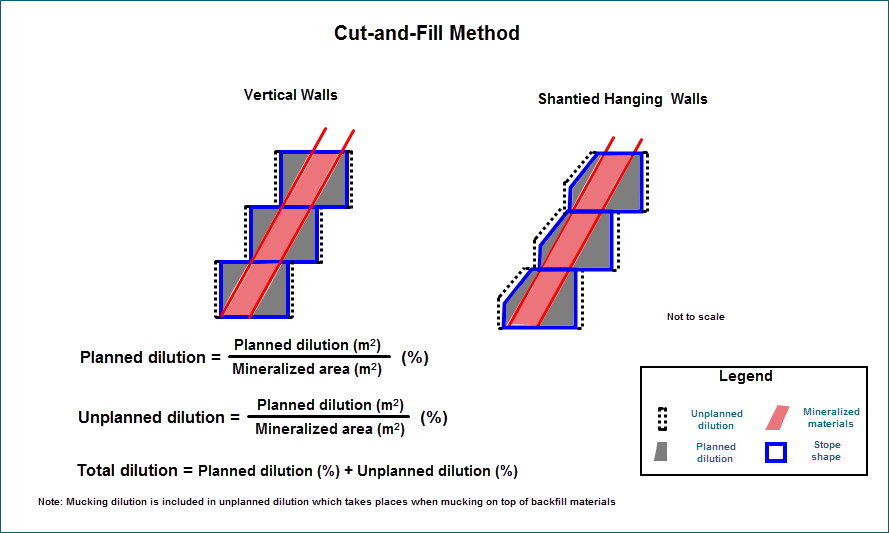

AMC utilized the following formulae to determine dilution. Dilution ratios were calculated for planned and unplanned dilution. Total dilution is the sum of planned and unplanned dilution (Figure 1.1 and Figure 1.2 ). This method has been selected from numerous alternatives for calculating dilution.

The optimum dilution is a trade-off against ore recovery. Given the value of the ore for this case study, recovery was given priority over dilution, with a target recovery of 100%.

Benchmarking and case studies

AMC used benchmarking and case studies to identify dilution experienced at different NV mines, guide equipment selection, drill-and-blast (D&B) designs, and technical services procedures and recommendations.

Equipment

AMC examined the existing fleet of stope equipment (jumbos, LHDs, longhole drills, and bolters) at the mine and established optimal D&B designs for the selected vein widths, dips, drift profiles (square and shanty), drift size (height and width), and mining methods, which could immediately be implemented to reduce dilution, without additional equipment purchases.

AMC also identified the optimal fleet of stope mining equipment for dilution minimization. This requires the purchase of small, low-profile equipment and reduced development sizes.

Optimized stope and drive dilution

AMC completed a comprehensive analysis to determine the minimized dilution for both LHOS and CAF using the formulae discussed. All of the selected vein widths, dips, drift profiles, and drift sizes were examined to minimize dilution and maximize recovery. The drift sizes considered had to accommodate either existing or optimal equipment.

In general, minimum dilution is achieved using the optimal equipment and smaller ore drives for the LHOS methods, or the lowest practicable drift heights for CAF.

Minimum dilution for LHOS ranged from 66% (1.5 m stope width, 0.5 m vein width) to 9%. For a 5 m vein width a minimum dilution of 9% is achievable in good ground with a 20 m sublevel interval and either a 5 m wide by 3 m high ore drive or a 5 m wide x 5 m high ore drive; in fair ground, the dilution projection increases to 10%.

Key results for CAF method was 28% for a 1.5 m vein width and 11% for a 5 m vein width.

AMC used the ideal stope and drive dilution results for the basis to create D&B designs, which included: slot raise, production rings and powder factors (PF) for LHOS. The D&B designs for CAF included: drill patterns, suggested explosive loading and PFs.

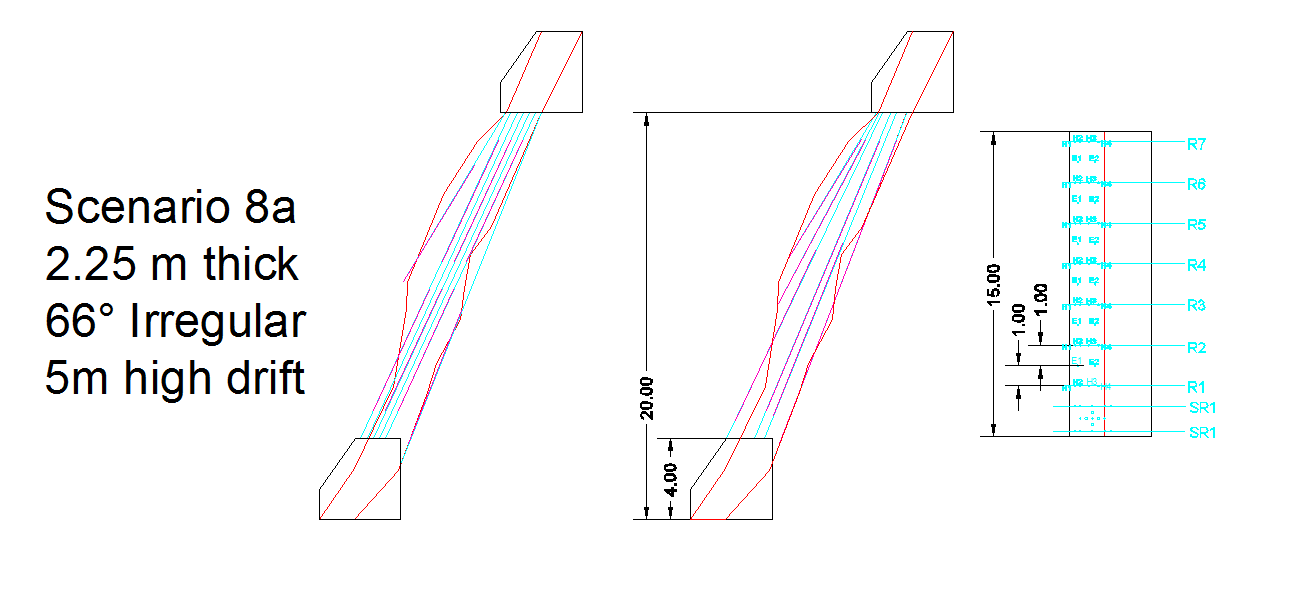

An example of LHOS design for an irregular vein shown in Figure 1.3.

1.1 Case study guidelines and processes to reduce dilution

The three main areas to target idealized dilution includes: drive dimension optimization, D&B practices, and overall quality control.

Ore drive:

- Narrower veins, equipment that fit in 2.7 m wide x 3 m high drift.

- Shanty ore drive backs.

- Minimize development into orebody HW.

- Review technical support processes for designing NV stopes.

Blast design:

- Slot development. Consider large relief raise (i.e V30 – 760 mm)

- Reduce drillhole size.

- Implement recommended drill patterns, including perimeter blast control.

- Use guide rods (reduce deviation).

- Stope blasting:

- Low-density emulsion in NV stopes.

- Implement the stope (longhole and ore drive) blast designs provided by AMC.

- Develop trial work process to optimize the D&B patterns and reduce dilution.

Overall quality control:

- All departments: Planning, survey, geology, geotechnical, ventilation and operations are to provide input and sign-off for stope and mine designs.

- Survey stope mark-up and a reference line.

- Implement surveyed drill set-up process (drill hole accuracy).

- Blasting engineer continuously involved with blasting crews.

- Cavity monitoring survey every stope blast.

- Regular, quantitative reconciliations between the design and the blast results. Share with stakeholders and implement changes.

Subscribe for the latest news & events

Contact Details

Useful Links

News & Insights